Connects to all your systems

What we do

Solve manufacturing challenges

by creating context from all your data

Root Cause Analysis

Get to root cause faster

Anvil connects operational signals and decisions into a coherent sequence, showing how failures developed across the system. Investigations converge quickly because the context is already in place.

Process Optimisation

Improve processes with system context

Anvil provides a system-level view of the factory, revealing how machines, people, suppliers, and rules interact. Teams can identify real constraints and improve performance.

Knowledge Management

Find institutional knowledge instantly

SOPs, maintenance logs, and transactional records. Turn decades of operational data into shared knowledge.

Audit & Compliance

Audit-ready in minutes, not weeks

Pull together batch records, deviations, CAPAs, and supporting documentation with a single query. Answer auditor questions on the spot.

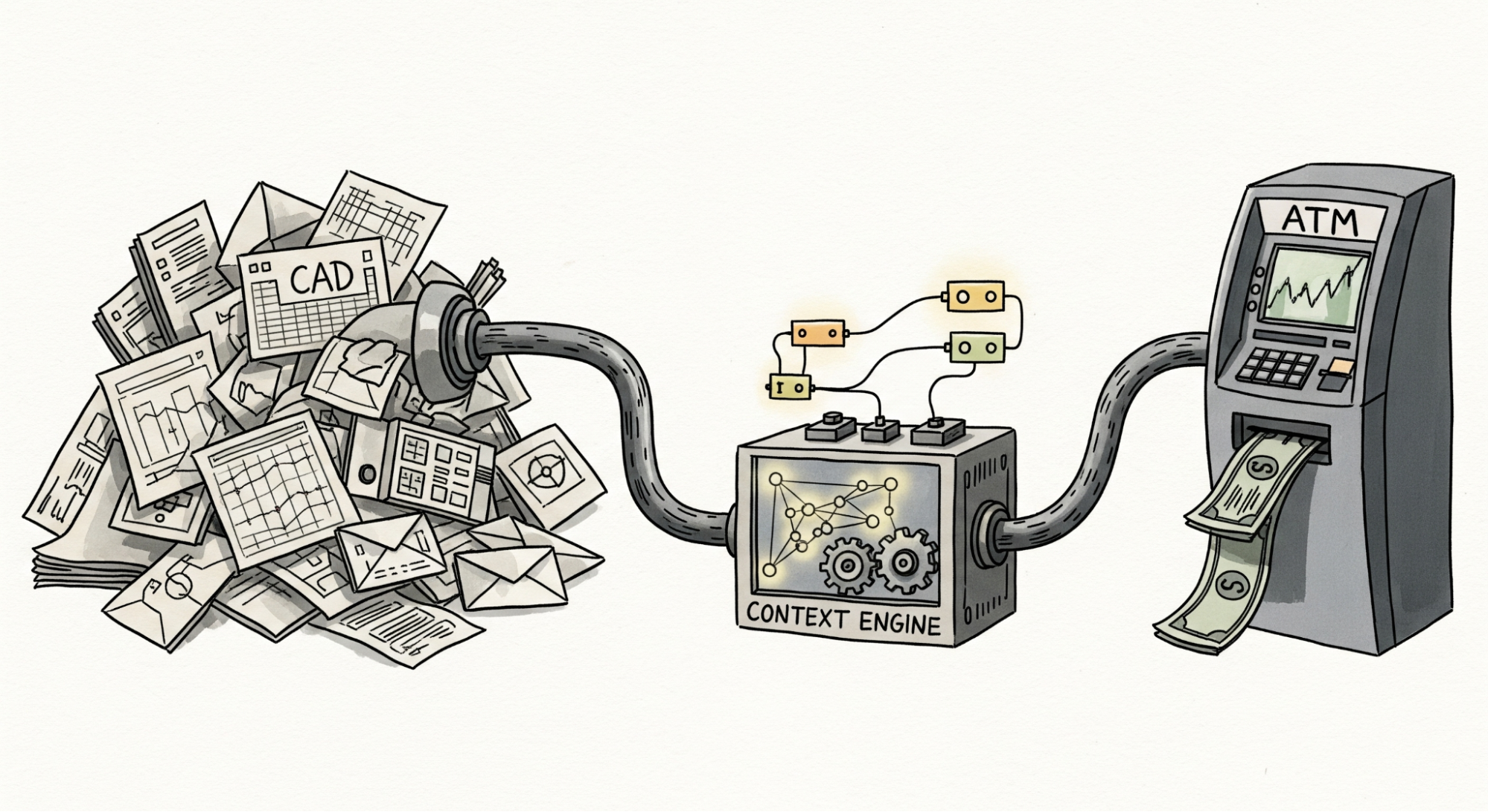

How we do it

Forge your operational context

from messy data

Connect all your data

Anvil connects to your ERP, MES, QMS, historians, and IoT devices. It also ingests documents, emails, SOPs, and unstructured data from SharePoint, Google Drive, and local storage.

Build your knowledge graph

Anvil's Manufacturing Context Model transforms your raw data into a structured knowledge graph - mapping relationships between assets, processes, people, and events.

What you get

Turn context into answers,

decisions, and actions

Ask questions, get answers

"Why did Batch 2847 fail?" Anvil pulls the deviation record, correlates it with sensor data, surfaces the relevant SOP, and traces similar incidents across sites.

Trigger actions automatically

When a deviation is logged, Anvil can draft the CAPA report, pull historical precedents, notify the right people, and update your dashboards automatically.

Build on the graph

Your knowledge graph becomes a platform

Use Anvil's SDK to build custom applications on top of your unified operations data. Create specialized tools or expose the graph to your own AI agents.

Insights

Factories Deserve Better

Support